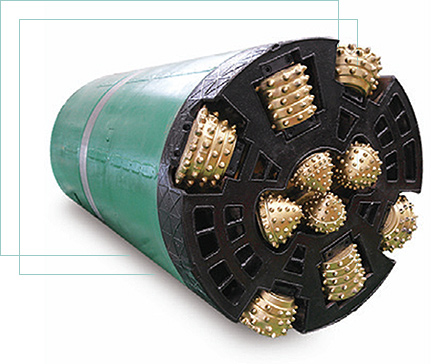

Semi-Shield TBM

Cobra method

This method enables economical construction by thrusting from small shaft

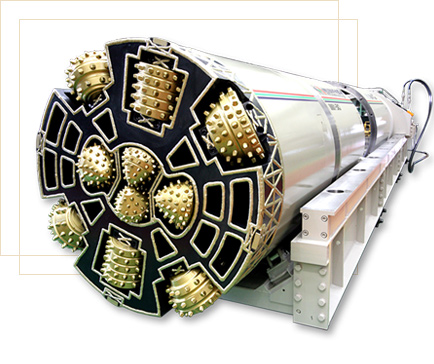

Semi-shield TBM can smash even bedrock

EM Korea bought from Taiko Techs the rights to manufacturing and selling its TBM

Cobra method TBM

EM Korea’s Cobra method semi-shield TBM can cope with from normal soil to hard rock. It securesthe best productivity with high bearing capacity and slurry process which has strong grinding and shortening construction time

It is semi-shield TBM which can deal with every type of soil from normal one to boulder.

It is suitable equipment to Korea where has lots of hard rock area. Also, economical construction is possible by thrusting through small sized launch shaft.

The size of equipment also small so that it does not occupy much space and it does execution with high output motor and tri-cone bit

Feature of Cobra method and applicable area

- ㆍHigh bearing capacity, slurry method

- ㆍPrevent rolling by use of joint pipe

- ㆍWorks well to bedrock by use of high output

motor and tri-cone bit

Main Components

-

- Tunneling Machine

-

• Cutter beat : Tri-cone cutter beat

• Direction modifying cylinder : 490kN x 3EA

• Cutter motor : 74kW (37kW x 2EA)

• Rotation : 10.08rpm

• Torque : 71.5kN·m

• Size : Φ1,220 x L4,206

• Weight : 8,130.1kg

-

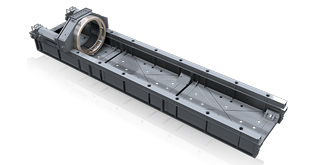

- Pipe Jacking (Pipe Jacking)

-

• Jacking force : 3,920kN

• Size : W1,565 x L7,584 x H1,400

• Weight : 6,346.6kg

-

- Hydraulic Unit (HYD. Unit)

-

• Motor : 15kW

• Discharge amount : 0∼24ℓ/min

• Pressure : 700kgf/㎠

• Pressure : 600kgf/㎠

• Size : W1,000 x L1,200 x H1,400

• Capacity : 1,000ℓ

• Weight : EMPTY 700kg, FULL 1,700kg

-

-

Slurry treatment device

( Tank, mud separator) -

• Form : SM-1.2

• Treatment amount : 1.2㎥/Min

• Treatment capability : 8∼10t/H

• Agitator pump : 5.5kW

• Cyclo pump : 7.5kW

• Vibration equipment : 1.2kW x 2EA

• Capacity : 8,500ℓ

• Weight : Tank 1,351.6kg

Mud separator : 602.9kg

-

Slurry treatment device

-

- Micro separator (Decanter)

-

• Form : DK-22

• Output : 22kW

• Treatment capability : 4∼6㎥/h

• Size : W2,335 x L840 x H1,550

• Weight : 3,206.8kg

-

- Lubrication System

-

• Form : MU-400

• Motor : 0.75kW

• Discharge amount : MAX. 9ℓ/min

• Discharge amount : Max 2MPa

• Discharge pressure : 1.5kW x 2EA

• Weight : 537.8kg

Cobra method machine enables to construct in many ways such as gas pipe, communication pipe, water and sewer pipe, ect

ㆍModel : CKE-1000 / CKE-1500

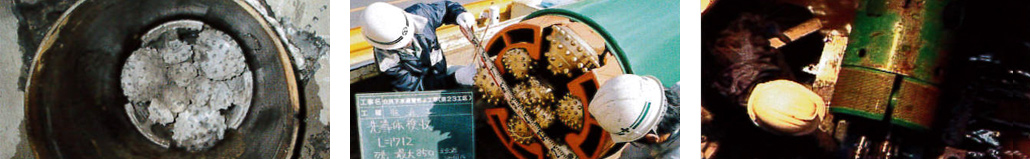

Pipe return method

The only TBM which is enable to excavate back and forth

Innovative method which do not need to construct receival shaft

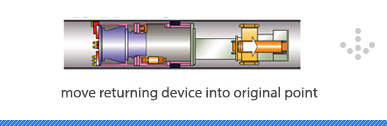

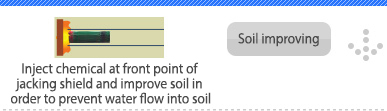

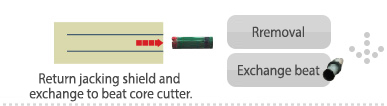

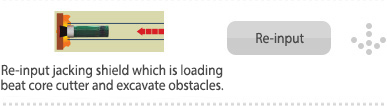

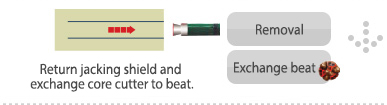

Thanks to self-return equipment load, jacking body can be returned from launch shaft and then exchange cutter, after that re-excavate

EM Korea has acquired the rights to the Semi-shield TBM-- the only TBM which has the ability to move both forwards and backwards, allowing it to return to the launch shaft upon completion of a project. One of another impressive feature is that this semi-shield machine is able to excavate in every direction include downward, upward, horizontal and angles. In addition, all the process can be controlled by automatic operating system. Not only thrust constructions but also foundation work, slope work, pipe routing work and water collecting work can be done. Also, it is possible to exchange the beats while excavating in accordance with changes of soil type. Minimum diameter of launch shaft is 2000mm and maximum long distance excavating is longer than 300m.

Feature of pipe return method and applicable area

- ㆍLeave thrust pipe and reduce cutter face so that it can move

back and forth also, re- input and re-excavating - ㆍLittle space is requiredfor the launch base,

existing pipe space may be used as a return shaft - ㆍIt is able to excavate in every direction

- ㆍLong distance drilling can be done at

more than 300 meters

- Leave thrust pipe and reduce cutter face so that it can move back and forth

-

- •Change bit depends on soil type, able to choose

slurry discharging method - •Soil improvement can be done inside of

the jacking machine body - •No need to take out thrust pipe

when error occurs

(minimizing environmental infulence)

- •Change bit depends on soil type, able to choose

- Little space is required for the launch base, so there is no need to construct a receival shaft

-

- •Minimum radius 2,000m launch shaft

(when jacking direction is horizontal) - •No need to construct receival shaft

- •It is accessible to existing buried pipe and

design space

- •Minimum radius 2,000m launch shaft

- It is able to excavate in every direction

- •Downward, upward, horizontal and angles

- Maximum long distance excavation can be done longer than 300m

-

- •Highly accurate measurement can be done

thanks to high functionalized electronic

device and precise management - •Direction modifying can be done in real-time

accurately

- •Highly accurate measurement can be done

Construction examples : pipe line constructions such as water and sewer / gas / communication / electricity. Direct connection into existing buried

pipe, water collecting well work, reinforcement work of tunnel entrance, ect.

ㆍModels : PKE-450 / PKE-650 / PKE-800 / PKE-1000 / PKE-1250 / PKE-1350

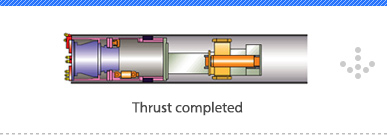

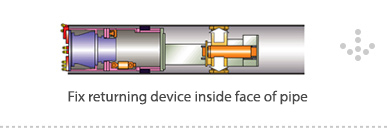

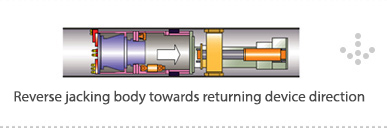

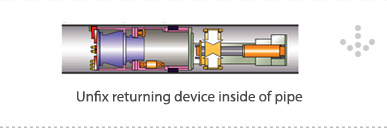

Thrust body returning process

Process of underground river

thrust work